⧵ Veer

⧵ Houston, TX ⧵ 2018

⧵ Veer

⧵ Houston, TX ⧵ 2018

⧵ Houston, TX ⧵ 2018

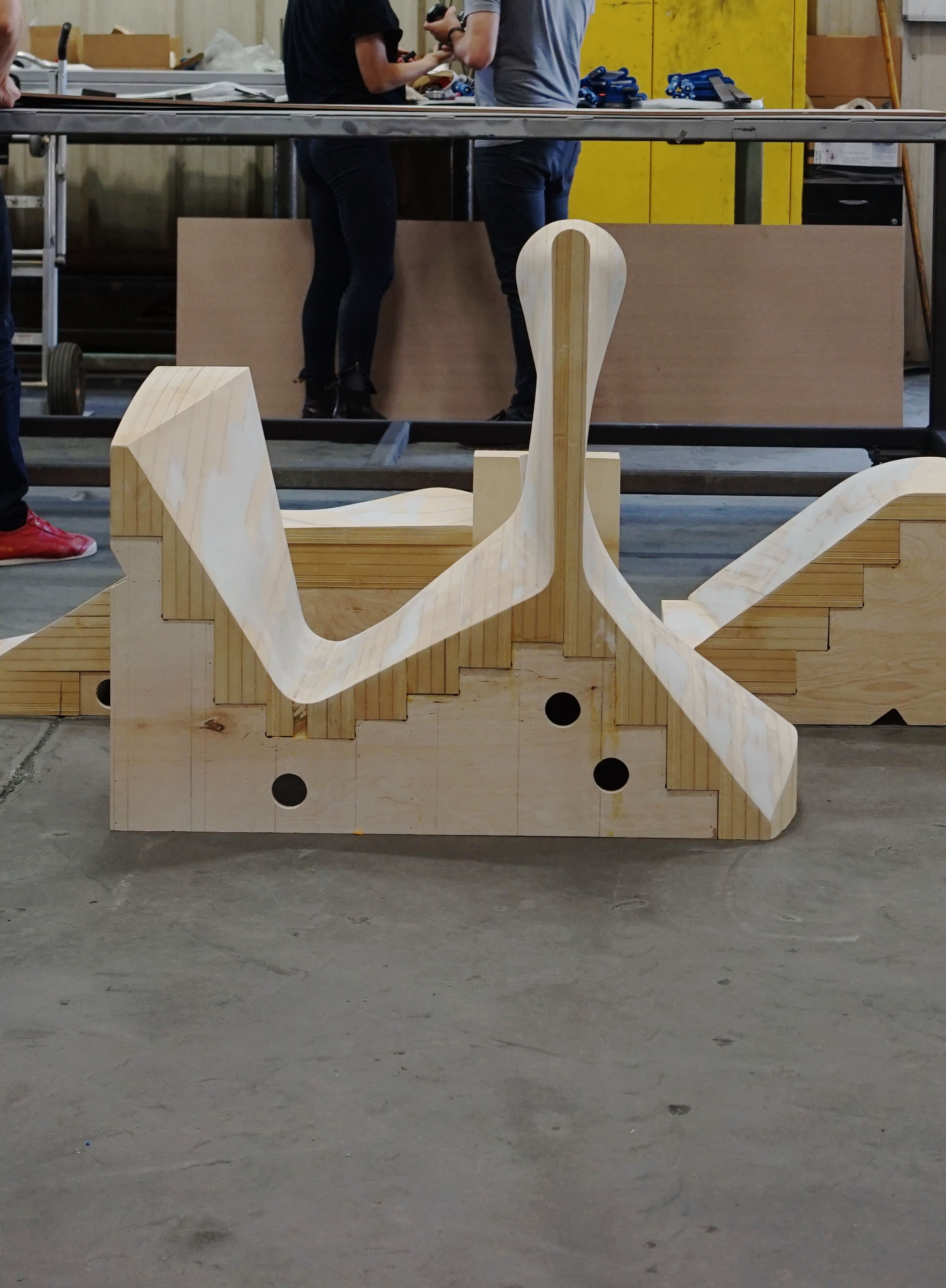

Veer is a chair prototype developed using a new biocomposite material. With durability and cost initial concerns, the examination looked to a biocomposite that incorporates rice husks, a rapidly renewable agricultural byproduct, and provides the durability, formability and strength of a composite with a surface quality more akin to wood.

With material properties much like the bent plywood and fiberglass chairs of mid-century, the design takes a cue from both. The concept begins with a single, filleted profile along one edge but replaces a logic of surface fillets with conic sections. The result is added strength, an ability to nest for shipping, a space for storage in the leg, and a subtle, iconic asymmetry. More complex curvature, achievable given the material’s plasticity, are also introduced to provide both added strength and comfort at the feet and chair back.

The design process utilized rapid prototyping of scaled models to test different geometric variations followed by a series of half-scaled prototypes formed from the biocomposite to evaluate the molding and thermoforming process which resulted in a five-part, double-sided mold CNC milled from MDF and strategically clamped.

Created with David Costanza.

With material properties much like the bent plywood and fiberglass chairs of mid-century, the design takes a cue from both. The concept begins with a single, filleted profile along one edge but replaces a logic of surface fillets with conic sections. The result is added strength, an ability to nest for shipping, a space for storage in the leg, and a subtle, iconic asymmetry. More complex curvature, achievable given the material’s plasticity, are also introduced to provide both added strength and comfort at the feet and chair back.

The design process utilized rapid prototyping of scaled models to test different geometric variations followed by a series of half-scaled prototypes formed from the biocomposite to evaluate the molding and thermoforming process which resulted in a five-part, double-sided mold CNC milled from MDF and strategically clamped.

Created with David Costanza.